Total # of Attendees: 17

Notes:

- Jim (president) opened the meeting at 7:33pm

- Bill Nyberg’s service is 3pm on Saturday at his home in Marlton

- Mike brought in thousands of small wood parts (dowels, blanks, wheels, etc.) that he had warned folks about.

- He got a call from an individual who had a business which was a manufacturer rep’s for wood product lines.

- They were moving the business and Mike was willing pick up their excess items for free.

- Mike asked for a donation to the Humane Society.

- The group took the opportunity to look through and see what they could use.

- Mark & Carl visited from the TSCA, Delaware River chapter of Traditional Small Craft.

- They found our organization from an advertisement on Craigslist (Mike placed it there).

- Website for their group: http://www.tsca.net/delriver/

- Karl Kramer, karlksr@comcast.net, 856-935-4564

- 2nd Friday at Bivalve for oysters & program

- A week from Saturday (July 16th) for Maritime festival (Bivalve, NJ)

- Delaware consignment shop, tool exchange: http://delwaretoolexchange.com

- Jim proposed to provide donation to Bill Nyberg’s family charity - $100. Club agreed

- Mike spoke about the North Bennet Street School in Boston

- Trade school for woodworking, been around for over 100 years

- Fundamentals of fine woodworking (2 weeks); mostly sharpen & tune your tools

- Seven in class, instructor was graduate of 2 year program

- Provided list of tools you need, or you can buy them there

- The sort of course Mike believes he should have taken 20 years ago

- Did a variety of projects -- by hand -- to work through your hand tool skills

- Dave discussed the 4-door chest he brought in

- Master class at Philadelphia Furniture Workshop

- Turned out well, fun class

- Impressive work

- General discussion on Philly workshop after Mario’s presentation in June

Chest made by Dave Potts

- Jim discussed his work with Urban Promise

- Worked on rowboats with young students

- Showed video of Bill Nyberg on the boats during the launching

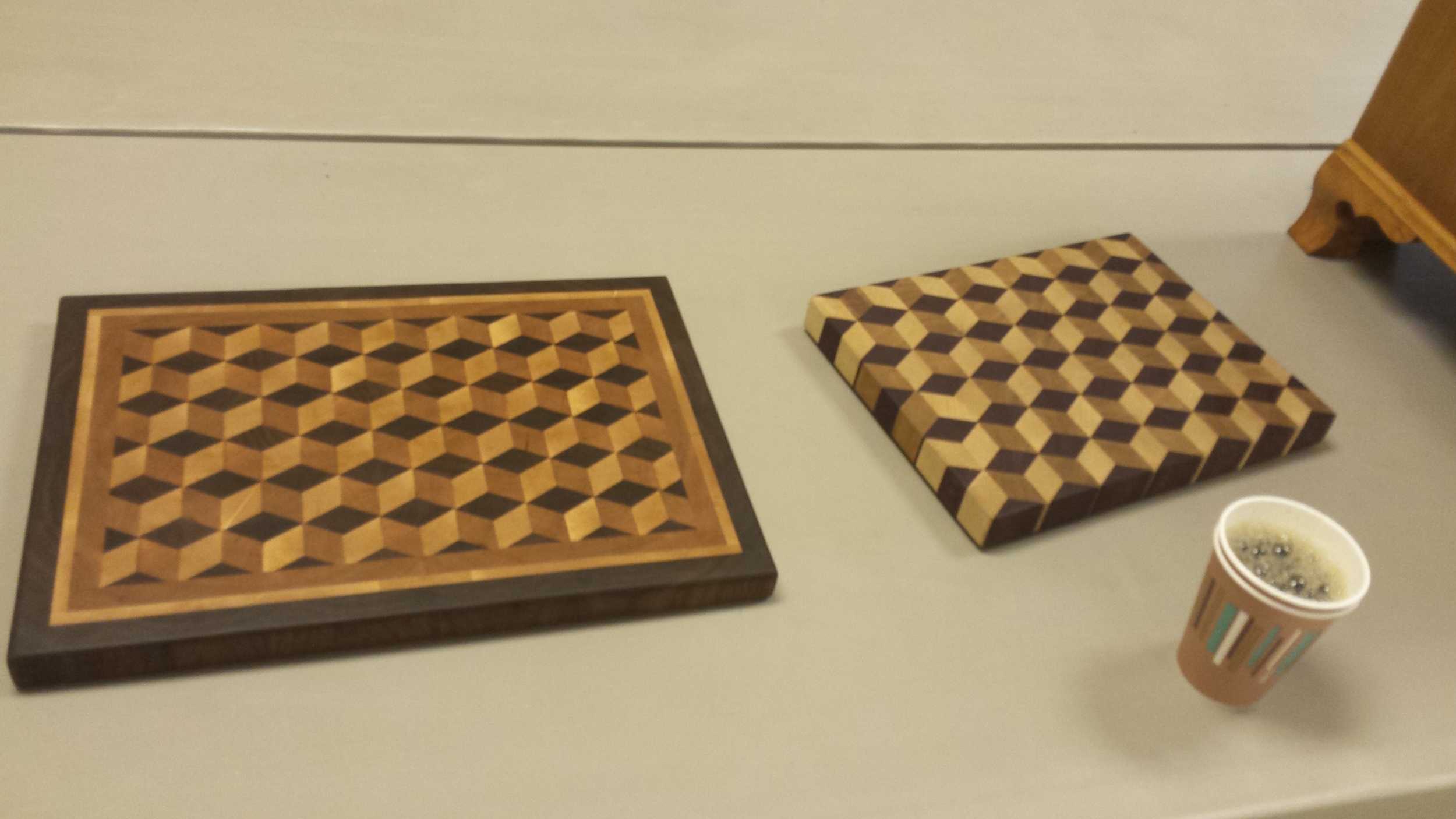

- Jim discussed his Freud videos and his 3D cutting boards

- Freud video: tumbling block cutting board

- Used Walnut, Maple & Cherry

- Made a special jig for clamping during glue up

- Need slow-setup glue, because it takes a long time

- Used router & jig to flatten, because he did not have a wide-belt sander

- Looks better with edge all the way around (instead of just on its own)

Cutting boards (coffee cup for scale)

- Problem discussed; John had a question on finishing oak

- Jefferson desk/table

- Open grained, so you won’t get smooth unless you close the pores

- One suggestion was sanding sealer, then tung oil

- Polyurethane also has been effective, or oil/varnish mixture

- Next Meeting Thu, August 4th

- Meeting closed at 8:47pm